HOW TO MEET MILITARY PACKAGING STANDARDS

Posted: updated March/April 2020 Author: Jim Higgs

TABLE OF CONTENTS

Why Does the Military Have Standards for Their Packaging?

What Are the Different Purposes of Military Packaging?

What Are the Different Military Packaging Standards?

What Are MIL-DTL-117 Standards?

Different Types of MIL-SPEC Packaging

How to Pick the Right Military Packaging for Your Applications

Although your packaging methods might be careful and exact, working with the military introduces a new level of standards and specifications to day-to-day operations. The Department of Defense (DoD) has several regulations to ensure military packaging is productive, safe and cost-effective.

Implementing these packaging standards is an admirable achievement of the military, and they have honed many portions of their preparation and shipping with dedication. Packing and shipping services have benefited from the structured expectations of the military by being involved in a greater degree of excellence.

However, it’s not unusual for contractors coming on the scene to have questions. The military’s procedures are backed with years of accumulated understanding, and it can be challenging for newcomers to pick up all the regulations. The military has a functional but elevated way to transport and store their equipment and essentials. This guide can help you understand and meet military packing specs.

WHY DOES THE MILITARY HAVE STANDARDS FOR THEIR PACKAGING?

Military leaders realized the need for thorough packaging standards over the years when the loss of transported resources hampered military efforts. Specifically, during the transition from World War I to World War II, shipping containers for provisions and equipment couldn’t stand up to overseas travel. Moisture and other elemental impacts were not accounted for, because the emphasis at the time was on conserving packing materials and exterior attractiveness for marketing purposes.

With little insight into solutions for packaging dilemmas, vulnerable containers made from commercial corrugated fiberboard continued to circulate while the level of contents rose. Overpacking was the military’s first answer to packaging setbacks, but “V-board boxes” crafted from sisal was the next.

Problems surfaced that compromised rations, medicine and information. There were also weaknesses in labeling containers and delivering them to the correct location. As these propositions continued to fail and hinder the flow of military operations, it became clear that sturdier vessels and attentive coordination were necessary.

Eventually, the military developed a protocol for protective containers, handling, inspection, transportation and storage, which pinpointed many of the issues and paved the way for more efficient practices. As the military honed the process, they found productive ways to reinforce distribution depots, control inventory and train personnel. At first, individual branches of the military services approached their packaging issues with their own specifications, but joint efforts did form a cooperative system for packaging during World War II.

After World War II, the DoD formed comprehensive packaging standards, which were further streamlined and implemented. The result was cost-effective and durable packaging that keeps the supplies safe and usable until they’ve arrived at their location and have been opened.

Overall, the reasons for military standards emerged due to shortcomings in packaging that delayed or hindered crucial functions. Military packaging standards protect equipment, assert combat readiness and ensure superior performance among all shipments.

WHAT ARE THE DIFFERENT MILITARY PACKAGING GUIDELINES?

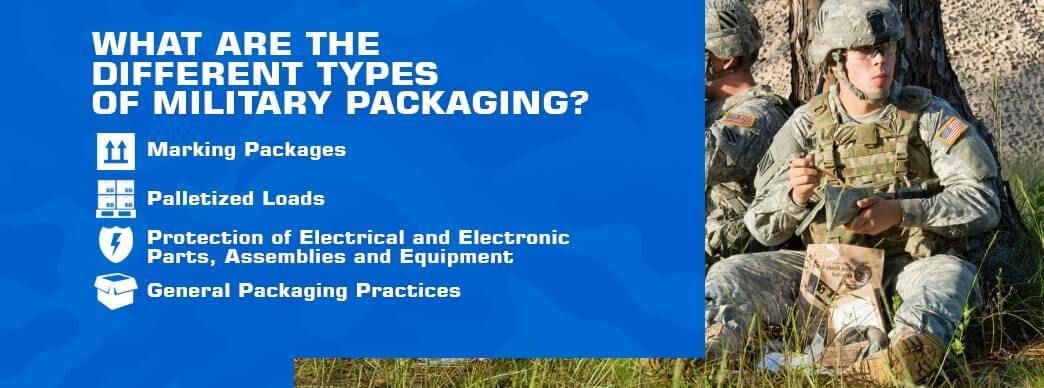

Military packaging consists of preserving and packing items with enough backings to withstand transport and stationary storage. However, there are four main categories of guidelines for different MIL-SPEC packaging standards that play substantial roles in the process. These standards cover different sizes, sensitivities, visual aids and policies:

1. MARKING PACKAGES

For shipment and storage, packages must have clear labels. This section of standards sets the bar for markings that can resist the elements and direct the items to the proper recipient. These specification standards are detailed in MIL-STD-130, MIL-STD-290 and MIL-STD-2073-1.

These stipulate the placement or size of bar codes, shelf life, warranties, warnings and special instructions, among other things. Not every surface can retain legible markings and not every ink or paint can suit a container, so the DoD goes over acceptable ways to communicate the package details.

These standards even cover procedures for unconventional packages like bundles and unit loads, demonstrating multiple possibilities for ease of identification.

2. PALLETIZED LOADS

Transferring unit loads of material on pallets requires specific guidelines in binding the items and stabilizing them. The DoD regulations for palletized loads help organize and secure collective quantities, using MIL-STD-129 and MIL-STD-290.

Making the best use of available space, the formations of the loads should stick to an appropriate size, pattern, type, wrapping and system. The pallet boards also meet rigorous requirements so the lumber and structure can bear the weight of the items. Strapping, supports and separators must also adhere to specific criteria, and you can follow the palletized methods to avoid complications in your military business dealings.

3. PROTECTION OF ELECTRICAL AND ELECTRONIC PARTS, ASSEMBLIES AND EQUIPMENT

The Electrostatic Discharge Control Program’s instructions cover the handling of items that static electricity could impair. These reactive items can break from electrostatic discharges that human touch, processing devices and some plastics can transfer. MIL-STD-2073-1, MIL-STD-2073-2 and MIL-PRF-81705E cover the packaging standards associated with electrostatic discharge.

Piezoelectric crystals, discrete semiconductors and micro-circuits are all parts that the military often ships, but these parts need a unique kind of packaging. These standards lay out the precautions necessary for shipping them, and protective covering can block these goods from damage.

4. GENERAL PACKAGING PRACTICES

Standard practices for military packaging encompass documentation and production. This is the primary section that informs contractors on the makeup, types and styles of bags and barrier material for packaging. MIL-STD-2073, MIL-STD-129, MIL-STD-1686, MIL-STD-3010 and MS20003 are standards that detail these practices.

These parameters can assist operational demands and minimize environmental impacts during shipping. From containers to quality assurance, the general packaging procedure expounds on the expectations of the military.

WHAT ARE THE DIFFERENT MILITARY PACKAGING STANDARDS?

The military uses a range of guidelines for shipping, transporting and storing goods. Some of the specific military packaging standards are outlined below.

1. MIL-STD-129 PACKAGING STANDARDS

MIL-STD-129 specifies the military markings that must be used for shipments and storage. These signs include labels, shipping tags, water-resistant envelopes, waterproof markings, identification bar code markings, markings to indicate special handling needs, labels for ammunition and explosives and more. Under this standard, a sign can be the numbers, letters, bar codes, labels, tags, symbols or colors applied to material packaging for identification purposes or to provide handling instructions.

A few of the many requirements under this standard include the following:

- Marking legibility, durability and color: Markings should be legible, durable and clear and should not fade.

- Size of marking: Unless otherwise specified, the size of identifiers should be in clearly visible capital letters of equal height. Lettering should be the largest size that is practical for the packaging dimensions. When the packaging space allows, stenciling and pre-printed markings should not be smaller than .09 inch.

- Ammunition and explosives packaging label requirements: Packaging containing ammunition or explosives may include a Navy ammunition logistics code (NALC) or a DoD identification code (DODIC) in addition to the 2D (PDF417) bar code.

2. MIL-STD-130 PACKAGING STANDARDS

MIL-STD-130 governs the identification marking of U.S. military property, including tagging methods such as commercial and government entity (CAGE) codes, the data universal numbering system (D-U-N-S), electronic serial numbers (ESN), enterprise identifiers (EIDs), human-readable information, machine-readable information (MRI), national stock numbers (NSNs), registration numbers, serial numbers, text element identifiers, unique item identifiers and more.

A few of the various requirements under this standard include the following:

- Methods of application: The required marking should be affixed or applied to a securely fastened identification plate, band, tag or label or applied directly to the surface of the item.

- Location, size and content: The marking should be legible during routine operational use. Item identification signs should be specified directly or in the document identifying the item to be marked.

- Permanency and legibility: Identification markings should be as permanent as the item’s standard life expectancy. Markings should also be able to endure the environmental tests and cleaning procedures specified for the object they’re attached too.

3. MIL-STD-1686 PACKAGING STANDARDS

MIL-STD-1686 determines the electrostatic discharge (ESD) control program for electrical and electronic parts and equipment. It governs assembly and equipment classification, sensitivity classification, protective coverings, marking of hardware, packaging, quality assurance and more for electrostatic discharge sensitive (ESDS) devices. It does not govern electrically initiated explosive devices, however.

Some of the requirements under this standard include the following components:

- Classification of ESDS parts, assemblies and equipment: Classification data should be used to ensure that the control program, design hardening, protected areas and handling procedures provide adequate ESD protection.

- Protective covering: ESDS parts and equipment must be safely enclosed in ESD protective covering or packaging when not in use or when removed from protected areas.

Contact us to learn about ESD bags that conform to MIL-STD-1686 packaging standards.

4. MIL-STD-2073 PACKAGING STANDARDS

MIL-STD-2073 specifies standard practices for military packaging. These packaged items can include objects delivered for deployment with military personnel during wartime, items that require reusable containers, articles intended for delivery at sea, goods intended for more than six months with the Defense Transportation and Distribution System and more.

MIL-STD-2073 covers requirements in the following areas:

- Development of military packaging requirements

- Factors and formulae establishing military packaging quantity per unit pack (QUP) and intermediate container quantity (ICQ)

- Containers

- Development of military packaging requirements for kits (parts and modification)

- Military packaging data forms

- Military packaging design validation

- Military packaging quality assurance

- Procedures for compliance with container design retrieval system (CDRS) requirements

- Military packaging requirement codes

5. MIL-STD-3010 PACKAGING STANDARDS

MIL-STD-3010 governs test procedures for packaging materials. These methods ensure the standardization of testing procedures for military packaging.

The test procedures covered under this standard include the following:

- Water vapor transmission rate

- Seam strength

- Puncture resistance

- Blocking resistance

- Resistance to curl

- Contact corrosivity

- Oil resistance

- Water resistance

- Water resistance of marking

- Static decay

- Transparency

- Thickness

6. MIL-I-8835 (FORMERLY MS20003-2)

MIL-I-8835 is a humidity indicator. It consists of a card that contains three spots, each one indicating a different level of humidity. The spots change color from blue to pink when the humidity threshold has been reached. From top to bottom, they measure 50% relative humidity, 40% relative humidity and 30% relative humidity, each one accurate to within 5%. The use of MS20003 can inform packaging facilities about the relative humidity in the packaging environment and whether it is suitable for sensitive applications.

Contact us to learn which of our products conform to MIL-I-8835 or any of the previously mentioned packaging standards.

WHAT ARE MIL-DTL-117 STANDARDS?

Unlike the MIL-STD standards listed above, the MIL-DTLs are detail specifications that outline how to achieve a specific requirement. One subcategory of packaging, MIL-DTL-117, specifies the nature of heat-sealed bags for military uses, like preserving food or storing supplies that are susceptible to corrosion. Heat-sealed bags can serve many purposes as personnel are planning for contingencies or conducting training scenarios. The DoD has set up in-depth criteria and checks to make these bags and pouches resilient and reliable.

1. MATERIAL

What the bags are made of influences their ability to keep out air and unwanted chemicals. MIL-PRF-121, MIL-PRF-131, MIL-PRF-22191 and MIL-PRF81705 and the most widely used materials. The composition of the bags has to fall within the relevant type and class comparable to the style and purpose. Warding off water or grease takes a treated substance, and foil, plastic, kraft paper or laminate can create to the protection your contents need. The thickness of the material is also managed to promote cost-efficiency.

2. CONSTRUCTION

The assembly process of the bags is critical to ensuring the quality and structure maintain the standard. By minimizing the differences, there can be fewer uncertainties.

The majority of the bag classes are formed from one or two sheets when the heat-sealable parts are faced inward. Electrostatic bags can be constructed from a single folded sheet and closed along either side or from tubing, in which case, there will be a bottom closure and no lip. Notches for easy tearing are also allowed.

3. MEASUREMENTS

Knowing the exact dimensions of products can make interchanges easy and smooth, especially when you’re managing military operations. The length and width of the bags are stated from the inside edges. Military tolerances are also assigned proportionally, and the seams created during the sealing task must remain minimal.

4. IDENTIFICATION

Recognizing the contents of packages can be simple when the exterior marking is deliberate. Numbers and capital letters in print are extremely readable, so military identification for these bags sticks to these specifications. The bag manufacturer and other details, including the variety such as “CALPAC ULTRAFOIL 500M MIL-PRF-131K CL.1,” are also printed onto the front.

5. SEALING

Paired with the unit packages, a guide with the jaw type sealer, band type sealer and rotary type sealer can help recipients understand the characteristics of the heat-sealed bags. Military standards indicate that the sealing information should accompany the bags for further use and storage.

6. SEAM STRENGTH

Retaining a stable seal can ensure that the bags will do their job. The seam strength has to hold up to the testing procedures and show no signs of weaknesses.

7. CRAFTSMANSHIP

The final products need to be skillfully created, which means splits, tears and cuts shouldn’t appear on the surface. Any extra matter or unsightly marks might be evidence of a malfunction. Even visual wrinkles and creases shouldn’t show up on bags, according to MIL-DTL-117.

DIFFERENT TYPES OF MIL-SPEC PACKAGING

Useful items need adequate protection from padding and sturdy containers. The DoD lays out their compiled packaging categories in their official documents, but the following summary can guide you through many factors in MIL-SPEC packaging. From the level of toughness to protective coating, the divisions and subdivisions of military packaging cover many aspects.

1. INTERIOR AND EXTERIOR

Interior packaging includes bags, sleeves and tubing. These range in sizes, but all the corresponding materials should have uniform shape, sizes and quantities. The DoD makes the following bag specifications:

- Bags, Heat-Sealable (MIL-DTL-117)

- Bags, Watervaporproof, Heat-Sealable, Complex (MIL-DTL-6060)

- Bags, Transparent, Flexible, Sealable, Volatile Corrosion Inhibitor Treated (MIL-DTL-22020)

Exterior packaging involves containers like boxes, drums and cans for additional shielding. Boxes are constructed from a range of materials, including wood, paperboard and metal. Dunnage, wraps and cushioning also can support transported material.

2. TYPES OF BAGS

Depending on the contents of the packaging, the type of bags can be heavy-duty, medium-duty, light-duty or extra-heavy-duty. Bags and wrapping can be rigid or flexible, too.

3. CLASSES OF BAGS

Each bag has a specific class assigned to it, representing the protective properties they hold. They can have one or many of the following qualities:

- Waterproof

- Watervaporproof

- Greaseproof

- Electrostatic protective

- Electrostatic and electromagnetic shielding

For instance, aircraft parts should have greaseproof bags because they should be guarded against residue.

The classes go from B to H, excluding G, and certain bag types must fall within the designated classes. Each class preserves its contents in a particular way. Some barrier classes include:

- Barrier Materials, Greaseproof, Waterproof, Flexible, Heat-Sealable (MIL-PRF-121)

- Barrier Materials, Watervaporproof, Greaseproof, Flexible, Heat-Sealable (MIL-PRF-131)

- Barrier Materials, Transparent, Flexible, Sealable, Volatile Corrosion Inhibitor Treated (MIL-PRF-22019)

- Barrier Materials, Transparent, Flexible, Heat-Sealable (MIL-PRF-22191)

- Barrier Materials, Flexible, Electrostatic Protective, Heat-Sealable (MIL-PRF-81705)

Desiccants and other preservative elements in packaging also have detailed specifications:

- Packaging Materials, Volatile Corrosion Inhibitor, Treated, Opaque (MIL-PRF-3420)

- Desiccants, Activated, Bagged, Packaging Use and Static Dehumidification (MIL-D-3464)

- Inhibitors, Corrosion, Volatile, Utilization of (MIL-I-8574)

- Corrosion Preventive Compound, Solvent Cutback, Cold-Application (MIL-PRF-16173)

4. STYLES OF BAGS

The styles of the packaging bags have three kinds — opaque, transparent or a blend with one side opaque and the other transparent. The various visibility levels help the military limit how many eyes see sensitive material.

HOW TO PICK THE RIGHT MILITARY PACKAGING FOR YOUR APPLICATIONS

When it comes to military packaging, deciding on the right packaging products to match your operations can be difficult. Here are some tips on choosing the correct packaging:

1. FAMILIARIZE YOURSELF WITH THE SPECIFICATIONS

Acquainting yourself with the military’s current standards for each part of the preserving, packing and packaging is valuable. With their intricate regulations, it’s vital to grasp the particulars of the documentation, wrapping and shipping methods. The military updates their specifications periodically, so regularly check the Defense Logistics Agency (DLA) to keep your knowledge relevant.

2. REVIEW COMMON PACKAGING ERRORS

Reoccurring problems in packaging can teach you what not to do as you orient yourself with the regulations. Often, labeling is off for military packages. Many forget to attach a proper shipping label, overseas route or bar code. Unsubstantial preservation is another mishap that can compromise packaged material. Avoid these setbacks and other common mistakes to stay on top of your operations and keep your products in top condition.

3. RECEIVE TRAINING AND USE RESOURCES

Universities and military schools both feature training courses on packaging, and some state centers host free training sessions. You can learn from seasoned professionals about your responsibilities and the practices of leading contractors and government workers.

Other tools like handbooks can educate you on the risks of non-compliance and explain military terms. Counseling representatives at the DLA are also worthwhile resources.

4. PARTNER WITH AN EXPERIENCED SUPPLIER

Choosing to work with a manufacturer who is proficient in military-standard products can add strength to your efforts, too. Suppliers who routinely interact with the military and defense contractors can enhance your business dealings.

Relying on skilled manufacturers can relieve the pressure you may feel to follow regulations. You can have peace of mind knowing they’ve successfully met the standards before, and they have a significant background helping the troops with suitable packaging.

CALTEX PLASTICS: YOUR MIL-SPEC PACKAGING MANUFACTURER

From pouches to sheeting, Caltex Plastics can preserve the integrity of your products during storage, transportation or retail sales. Our products are laboratory tested to ensure they meet stated specifications, preventing physical contamination. The barrier properties of our materials are within indicated tolerances, and our cost-effective solutions are ideal for MIL-SPEC packaging.

With the largest selection of rollstock on hand, we are ready to help you find the packaging items you need. Come join us in our pursuit of upholding military packaging standards.

Caltex Plastics operates 24/7 to provide you with outstanding service and delivery. For more information, contact us today by filling out our form or calling 800-584-7303.