HOW PACKAGING CAN EXTEND FOOD SHELF LIFE

Posted: August 30th, 2019 Author: Jim Higgs

TABLE OF CONTENTS

How Does Food Spoilage Occur?

Methods to Extend Shelf Life

How Packaging Can Extend Food Shelf Life

Types of Barrier Packaging That Reduce Food Spoilage

How to Choose the Right Food Packaging for Your Product

As a food or beverage product manufacturer, extending the shelf life of your products provides numerous benefits. It gives you more time to transport and sell your products and reduces inventory shrinkage due to spoilage, which translates to lower costs and more goods making it to consumers. It also means you can reach customers located further away from your facilities. Additionally, longer shelf life is convenient for customers, so it can increase your sales and your business’ reputation.

Food manufacturers can use numerous strategies to extend shelf life of food products and reduce inventory spoilage, and improving packaging is one of the most fundamental of these. Let’s take a closer look at these strategies.

HOW DOES FOOD SPOILAGE OCCUR?

Food spoilage is a naturally occuring process that makes food unsuitable for consumption and may alter the color, texture, odor and taste of food items. Spoilage affects food quality and may also impact food safety. Various factors can lead to food spoilage, including the following.

- Microorganisms: Various type of microorganisms, including bacteria, molds and yeasts, can cause food to spoil. Spoilage microorganisms typically cause food to look or smell unappealing, while pathogenic microorganisms may not cause any noticeable change in appearance, smell or taste, but can cause foodborne illnesses.

- Enzymes: Naturally present enzymes are what cause fruits and vegetables to ripen. As produce ripens, its color, texture and taste will change.

- Air: When air interacts with components in food, it can cause changes in flavor, color and nutrient content. This process is called oxidation.

- Light: Exposure to light can lead to loss of color and nutrients. It may also result in the oxidation of fats.

- Pests: Insects, rodents, parasites and other critters can get into food, damaging it and leaving it vulnerable to spoilage.

- Physical damage: Damage to food or packaging can make food products more vulnerable to other types of spoilage. Examples of physical damage include bruises and cracks on produce, as well as ripped or dented packaging.

- Temperature: Food deteriorates and microorganisms grow more quickly at higher temperatures.

- Time: Time is an essential factor in food spoilage. Microorganisms need time to grow, and processes such as oxidation and enzyme action take time to occur.

METHODS TO EXTEND SHELF LIFE

Food manufacturers need to consider food spoilage risks at all phases of the production and distribution processes. They use many different techniques to increase the shelf life of their food products, including inhibiting microbial growth, inactivating microorganisms, protecting food from physical damage and more. Some of these methods are as follows.

- Freezing: Freezing foods prevents microorganisms from growing and slows down enzyme activity. Manufacturers use this method for a variety of food products, including fruits, vegetables and meats.

- Hot-filling: Because heat can destroy microorganisms and sterilize food containers, it can help extend the shelf life of products such as juices, jams, soups, sauces, syrups and spreads. Hot-filling involves heating the product, then placing it in a glass or hard plastic container and capping it before rapidly cooling it.

- Drying: Because microorganisms need water to grow, drying a product is an effective way to prevent microorganism growth. Food drying is a time-honored method of food preservation.

- Fermenting: Fermentation is another technique of preserving food that has been in use for many years. The process involves using bacteria and enzymes under controlled conditions to convert carbohydrates, starches and sugars into alcohol or organic acids. The microorganisms digest spoilage-prone components of the food, helping preserve it and changing its flavor and texture in desirable ways.

- Oxygen absorbers and antioxidants: Adding oxygen absorbers — which contain an iron powder that reacts with oxygen and absorbs it — to sealed food packages prevents the growth of spoilage microorganisms and protect against insect damage. You can also add antioxidants, either natural or human-made, directly to food.

- Pasteurization: Pasteurization involves using heat to process foods and reduce microorganisms that may cause food to spoil or cause disease.

- Irradiation: Irradiating foods using gamma rays, X-rays or electron beams reduces or eliminates microorganisms and insects, delays ripening and sterilizes food.

- Temperature control: It is essential that food producers keep food at the proper temperatures through the production, packaging and distribution processes.

- Packaging: Packaging plays a critical role in extending the shelf life of food products. We’ll explore how packaging can help prevent food spoilage in the next section.

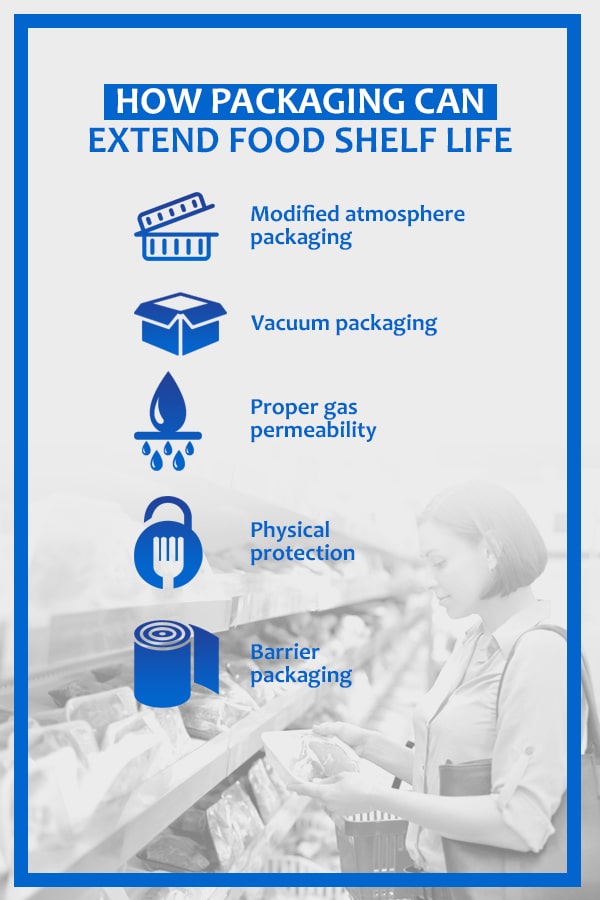

HOW PACKAGING CAN EXTEND FOOD SHELF LIFE

Packaging can help protect food from the various factors that may cause spoilage, so there is a direct link between food packaging and shelf life. Many different kinds of packaging extend shelf life, and various types of packaging that reduce food spoilage focus on protecting against different threats. Here are some of the ways packaging can extend shelf life.

- Modified atmosphere packaging: This process involves replacing the air in a package with another gas mixture to prevent oxidation. Optimizing this gas mixture according to the ideal conditions of the packaged food helps preserve it.

- Vacuum packaging: In this process, you remove as much of the air as possible from a package, and then seal it so minimal air remains in the package. The package will also have low oxygen permeability. Use this method for foods that do not need air to stay fresh.

- Proper gas permeability: For products that need air to remain fresh, you need to choose packaging that has the proper permeability based on the rate of oxygen transmission of the food products. This packaging may contain tiny holes or use a material with optimal gas permeability.

- Physical protection: Packaging also physically protects food items, which is crucial for preventing damage that can make food more vulnerable to other spoilage risks.

- Barrier packaging: Packaging may contain a foil, metalized or clear barrier that protects the product from oxidation, moisture and other risks.

TYPES OF BARRIER PACKAGING THAT REDUCE FOOD SPOILAGE

At Caltex Plastics Inc., we offer foil, metalized and clear barriers that help protect food and beverage products. These barriers are ideal for storing and protecting a range of food items, including meats, frozen foods, dried foods, snack foods, food rations, spices, powders and liquids. Let’s look at each of these types of barrier products.

FOIL BARRIERS

Foil barriers are excellent for protecting against oxygen, light, moisture and odors, and are useful for vacuum packing and long-term storage applications. The foil barrier materials we offer include:

- CALVF4 is a Mylar material with a polyethylene layer that’s laminated to a layer of aluminum foil. CALVF4 is ideal for foods that require low oxygen levels, and opaque bags made from this material act as a barrier against oxygen, light and moisture.

- CALVF4N is made from a foil/poly laminate with a nylon outer layer and offers full protection against oxygen, light and odors. This durable material creates a strong oxygen barrier and has excellent puncture resistance, which makes it ideal for vacuum packing products with sharp edges or points. CALVF4N’s interior sealing film also helps increase seal strength and prevent leakage.

- CALVF4C is ideal for products that require low oxygen levels and provides protection against air, odors, light and moisture. It has a wide range of uses, including vacuum packaging.

METALIZED BARRIERS

Metalized barriers are a water-resistant packaging material that protects against moisture, oxygen, odors and other factors. Our metalized packaging materials are useful in odor barrier, vacuum packing and decorative applications, and we offer numerous metalized barrier products, including standup bags and zipper bag packaging. The metalized barrier materials we offer include:

- CALVF4M offers excellent protection against moisture and is ideal for dried foods, powders and liquids. With this material, you can store powders and other food-related products for one year after the manufacture date if you keep the product at between 60 and 80 degrees Fahrenheit and 40 and 60% humidity.

- CALVF4M 2.5 is slightly thinner than CALVF4M, but is still an effective way to protect liquids and dry foods from moisture and corrosion. It also allows you to store products for one year after manufacturing at between 60 and 80 degrees Fahrenheit and 40 and 60% humidity.

- CALPAC 100 is an ideal vacuum packaging material for dried foods, powders, liquids and frozen foods and is useful for long-term storage.

- CALPAC 1500 is an exceptional dry packaging bag that’s ideal for dry foods, food rations, powders and other products that require extreme moisture protection. It features a vacuum packaging design, high puncture resistance and a low moisture vapor transmission rate.

CLEAR BARRIERS

Clear barriers protect against oxygen, moisture and odors, while still allowing shoppers to see the products. Our clear barrier bags are useful for packaging a wide variety of food products in long-term storage, vacuum packing and odor barrier applications.

- CALVAC 6X, a multi-layer material made with laminated poly nylon film, is ideal for vacuum sealing poultry, beef, fish, cheese and other perishable goods. It provides superb flexibility, strength and clarity, performs better than coextruded film and can withstand refrigeration and freezing.

- CALVAC 6X 5.0 is a heavy-duty version of CALVAC 6X. It features a thicker construction and a stronger seal, while maintaining flexibility and clarity. Its thicker construction makes it useful for packaging items with sharp edges or points, and its durable seal makes it ideal for long-term storage and food ration applications. Like CALVAC 6X, it can withstand refrigeration and freezing and outperforms coextruded film.

- CALPM4 features an outer layer of polyester and provides a simple solution that protects against moisture, oxygen and odors. CALPM4 bags provide substantially improved protection against oxygen, as compared to similar polyethylene bags.

HOW TO CHOOSE THE RIGHT FOOD PACKAGING FOR YOUR PRODUCT

How do you choose the food packaging material that’s right for your product? You should consider numerous factors, including the following.

- Spoilage risks: Increasing the shelf life of any food product requires you to evaluate the factors that are most likely to cause spoilage. What are the most significant risks for your product when it comes to spoilage? If your product is especially sensitive to oxygen, you’ll need to use a material that provides a strong oxygen barrier, such as CALVF4N or CALPM4. If puncturing or tearing the package is a bigger risk, use a material with a thick construction, like CALVAC 6X 5.0 or CALVF4N. Take time to assess the risks of food spoilage and choose a material that offers sufficient protection against those factors.

- Preservation methods used: The other food preservation methods you use may also play a role in which risks you need to protect against. For example, if you’re adding an oxidant to your product or an oxygen absorber to your package, you might not need as much oxidation protection from your packaging material. If you will be freezing your product, make sure the material you use can withstand the temperatures.

- Expected shelf life: You will also need to consider the minimum shelf life you want your product to achieve, and how much to prioritize extending shelf life beyond that timeframe. Determine the shelf life each type of material can provide for your products, and choose one that helps you meet your goals while balancing other factors.

- Customer expectations: Your customers should always be a top consideration when choosing packaging materials. What do your customers expect from your product? If they prioritize a long shelf life, you need to select a material that will provide that. They might also value being able to see the product before purchasing it, in which case a clear barrier would be the best choice. If your customers value natural foods and products without preservatives, you will need to rely more on packaging.

- Cost: Cost is an essential factor in determining which type of packaging to use. Evaluate the cost of each packaging material and the financial benefits it offers to ensure you’re choosing a product that will provide the features you need while remaining within your budget.

THE CALTEX PLASTICS DIFFERENCE

Another way to ensure you end up with the right packaging material for your food products is to work with an experienced packaging company like Caltex Plastics. We’ve been providing our customers with high-quality packaging materials to help them protect their products since 1984, and we can help you find the right materials for your needs.

Improving your packaging is one of the best ways to reduce food spoilage expenses and extend shelf life, and we have the packaging materials you need to help you meet your goals. We offer a variety of FDA-approved foil, metalized and clear barrier products that are ideal for food packaging and extending shelf life, as well as a range of other custom bags, pouches, sheeting and tubing products.

We’re dedicated to cost-effectiveness, quick delivery and high-quality products. To learn more about how our solutions can help you increase the shelf life of your food products, contact us today.